Language

▼

Language

▼

More Language

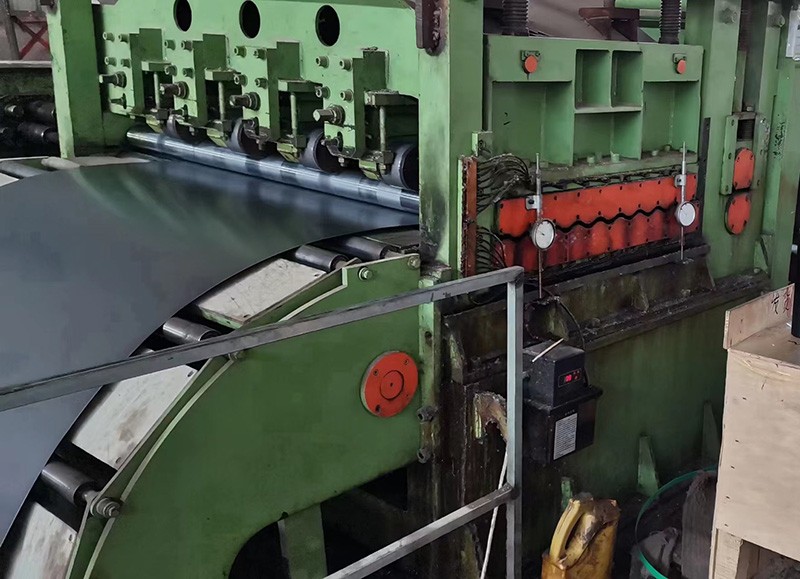

1. Kaiping machine equipment is an automatic processing equipment that processes rolled plates into the required fixed length dimensions through methods such as unwinding, feeding, longitudinal cutting, and stacking. There are axis and column devices such as loading carts, guiding devices, and hydraulic loops in the middle. It can be used for unwinding, leveling, cutting into a certain length, and cutting metal coils into flat plates of the required length, and then stacking them up. Suitable for processing of cold-rolled, hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various metal materials after surface coating.

2. Traditional Kaiping machine equipment uses a frequency converter to control the fixed length of the processed sheet metal, which often causes the motor to slow down and stop before reaching its position, leading to inaccurate positioning and low precision in sheet metal processing. Moreover, due to the long acceleration and deceleration time of the frequency converter, the processing efficiency is low. Combining programmable controllers and touch screens for centralized control, it has three characteristics: high degree of automation, high production efficiency, and high processing accuracy. Roll feeding can achieve smooth completion of each process in one go, effectively reducing labor intensity for workers, improving efficiency, and offering high cost-effectiveness.